Tyres - testing rig and selection

In Greenpower, overcoming rolling resistance makes up a significant portion of the energy consumed over a race. The style of cars means unexpected tyres are often used, e.g. those from Brompton bicycles. Given the lack of high-performance Brompton bikes, there has been very little testing on their tyres rolling resistance, and so we took it upon ourselves to build a test rig and determine which tyres were the best.

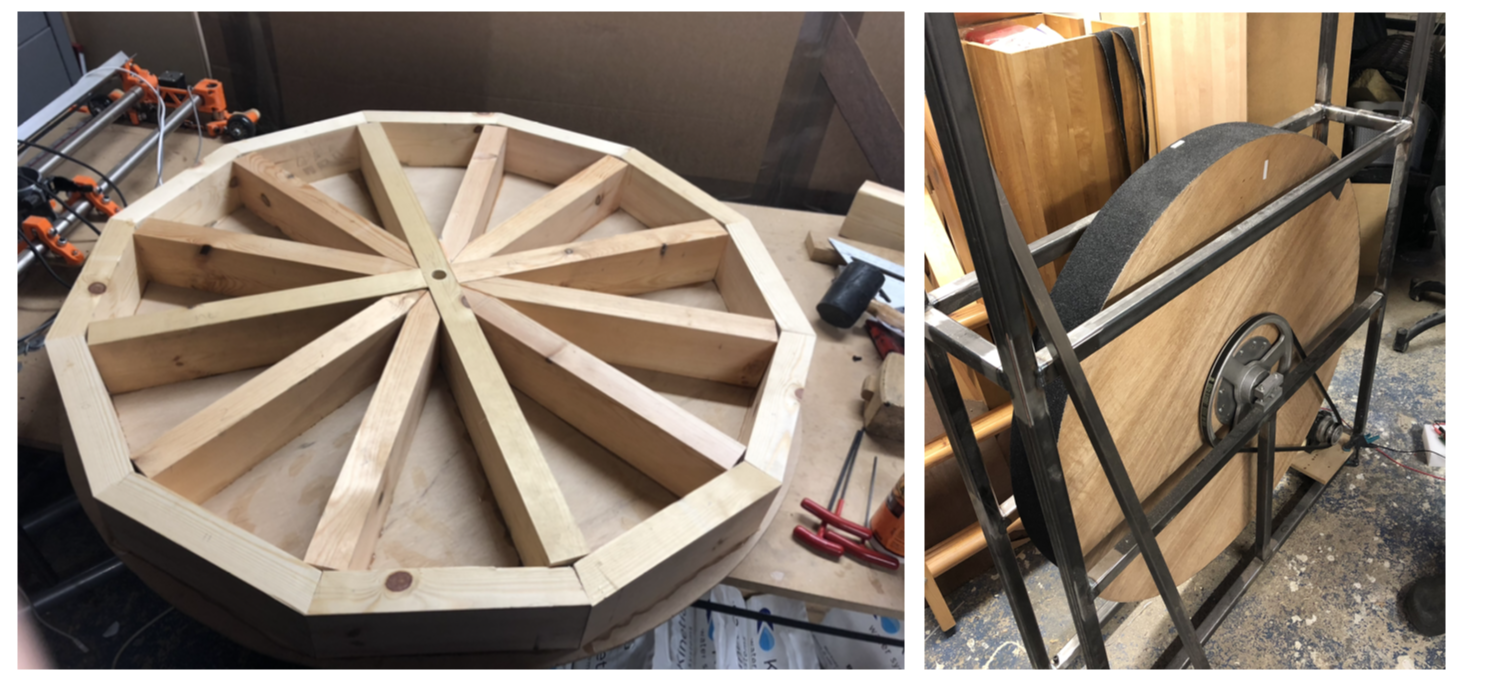

Internal structure and final assembly of rolling resistance test rig.

A 1m wooden drum was constructed akin to a wagon wheel and mounted to a TIG welded steel frame. This construction method was chosen so that the drum would have a large rotational inertia. The sides of the wheel were clad and finished to seal the wood and stop it expanding/contracting with changing weather conditions. The size of the drum was chosen to be large so that tyres rolling on its outer surface would experience an almost flat surface at their contact patch, akin to the road. A non-slip surface coating used for stairs at concerts was applied to the outside of the drum as this mimics the effects of tarmac without featuring sharp stones that would cut and degrade the tyre rubber. After balancing the wheel could be spun up to a specific RPM using an electric motor and held there with PID control. A swing arm was used to mount a wheel with the test tyres on, allowing a specific force at the contact patch to be applied.

Tyre running on rig with weight hanging off swing arm to produce the desired reaction force at the contact patch.

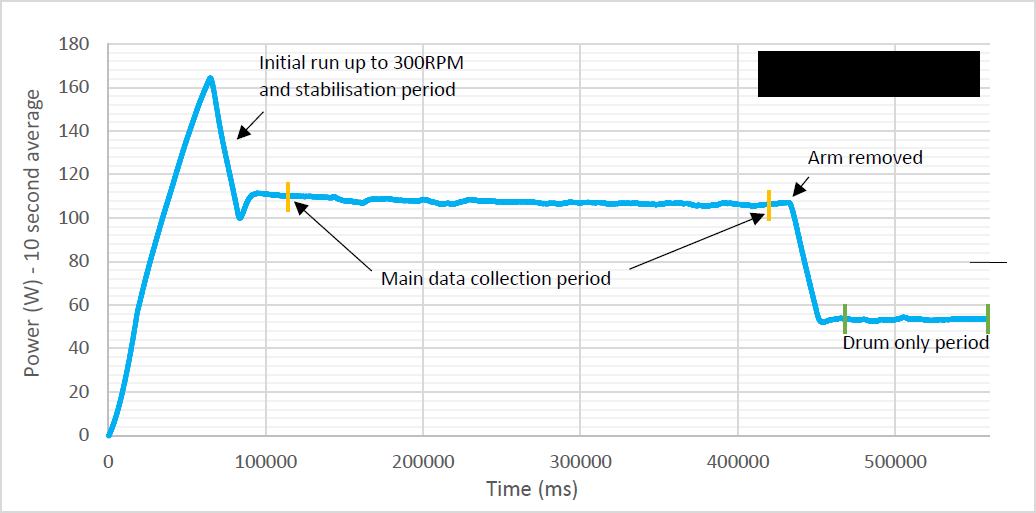

By measuring the power consumed by the electric motor being used to spin the drum and tyre and then removing the tyre to determine the power used just to spin the drum, it was possible to determine power consumption values for each make of tyre. Results showed extreme differences between the best and worst and allowed us to make an informed decision on which tyres to use for TMM.

Example of power consumption results collected during testing.