Topology optimisation of the front wheel structure

The metallic components on the car are designed to be lightweight to reduce the rolling resistance experienced by the tyres, all whilst maintaining appropriate safety factors.

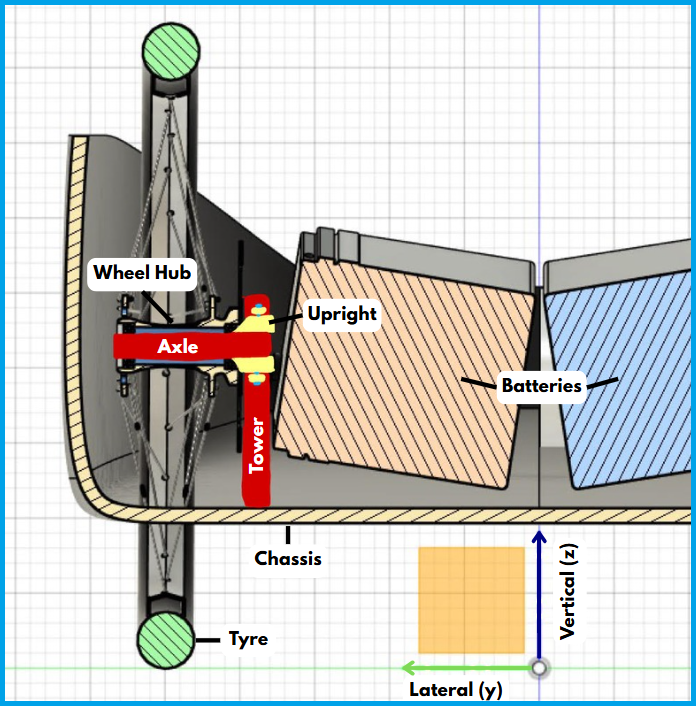

Cross section through the front axle showing the limited design space that the front structure can occupy.

The batteries on TMM are placed between the two front wheels at specific angles to exploit regulations for aerodynamic gain. This leaves a very small design volume for the structure (tower + upright) holding the front axles to the base of the monocoque chassis.

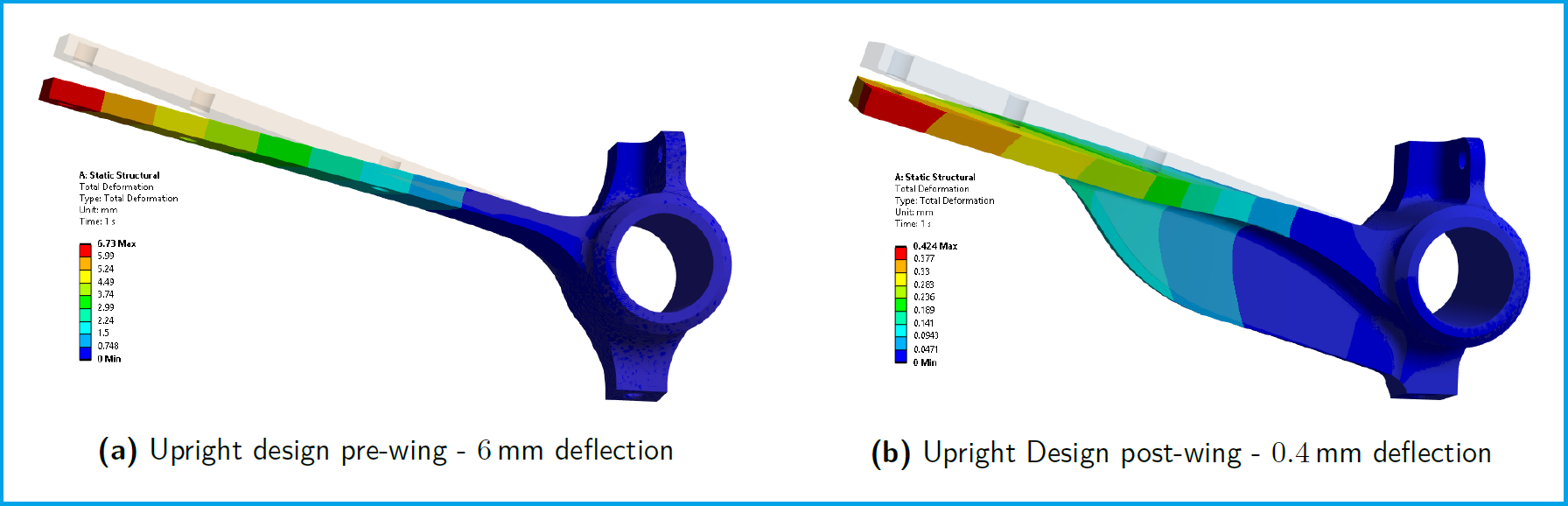

Classical Finite Elements Analysis (FEA) techniques were used to inform the design of all metallic components on the front structure. Obvious improvements to e.g. the upright steering arm deflection were found by manually adding efficient second moment of area through a conventional stiffening ‘wing’.

FEA of the front uprights showing how simple modifications can improve part stiffness.

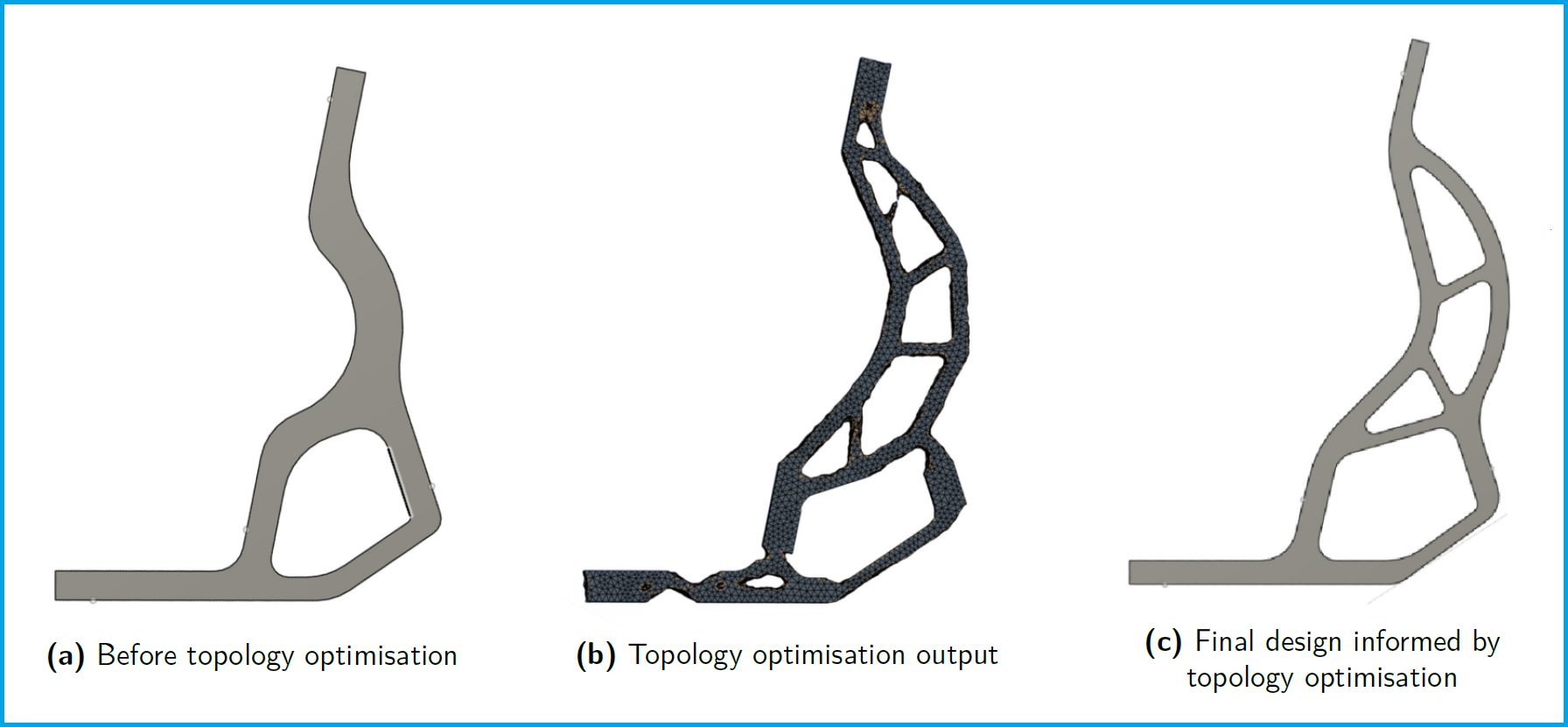

However, structural optimisation is slow when manually iterating between CAD and FEA. Given the batteries have predetermined a constraint volume, the use of automatic design techniques such as topology optimisation provides a simple way to generate lightweight structures that can then be verified using the original FEA methodology.

The Solid Isotropic Material with Penalisation (SIMP) method was predominantly used within ANSYS Mechanical, with extrusion-based manufacturing constraints being enforced to ensure the final parts could be simply manufactured on a 2-axis waterjet and or 3-axis CNC router.

Topology optimisation process for the brake calliper mounting component.

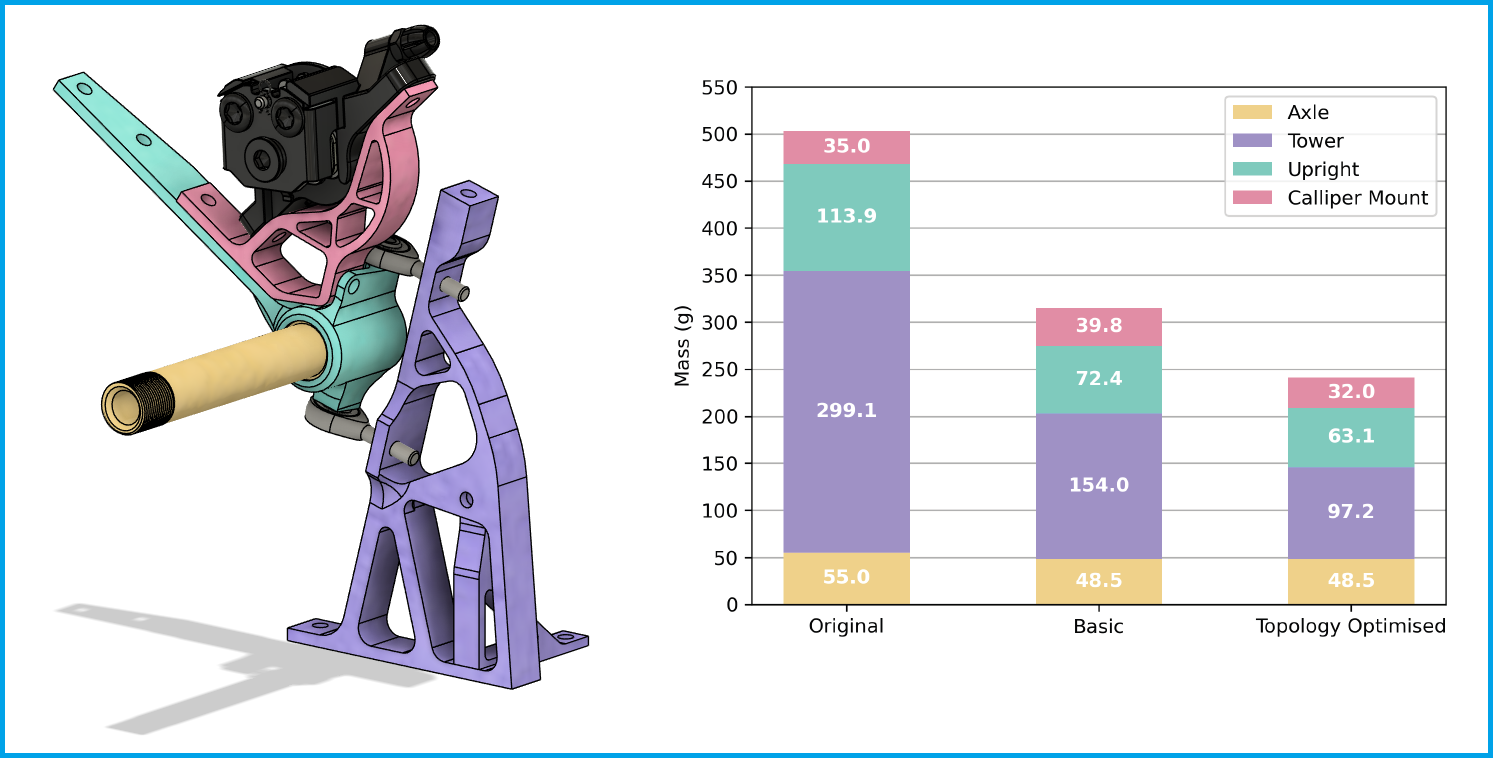

All components were tested both individually and as an assembly against a wide range of boundary and loading conditions, simulating longitudinal, lateral, vertical, and braking loads, plus their combinations.

Final front left assembly with component design informed by topology optimisation.

The final design for the front structure includes the axle and brake calliper alongside three components each with a design informed by topology optimisation. The result was an over 50% reduction in total mass for an equivalent maximum von Mises stress and a reduced maximum deflection.

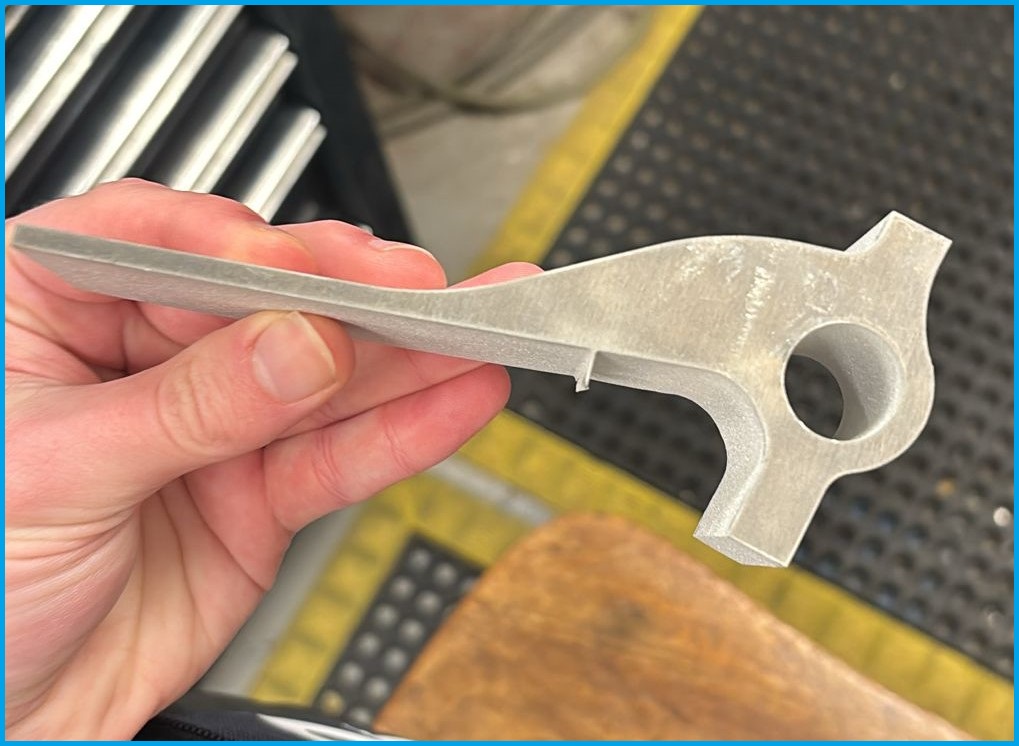

Front upright after waterjet cutting and before CNC finishing.

The parts are currently being manufactured, with the bulk of the work being handled by a 2-axis waterjet before the finishing pass is conducted on The Garagistas’ custom 3-axis CNC router.

This project was run by Ash Johnson as part of a University of Southampton final year Group Design Project.